The other day I

rushed an etching of my

ATtiny Programming Shield just to try out the process. The results weren’t that great. In fact, they were’t even usable. However, I figured with a little more attention to detail and a little more time vested, I’d yield a board that was usable.

Since it was Saturday, I had all day to mess around with it. I took my time this time. Unfortunately, it wasn’t to be. The results were actually worse than when I rushed it.

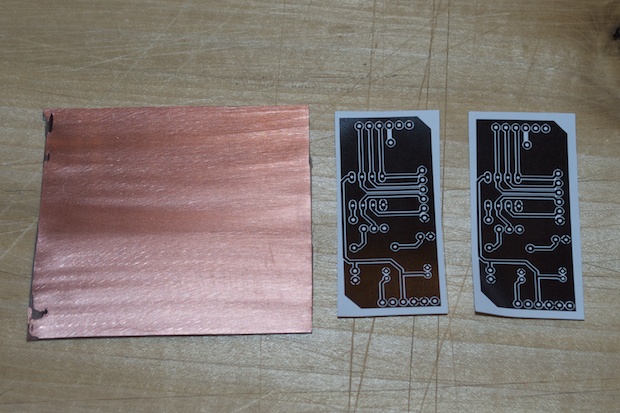

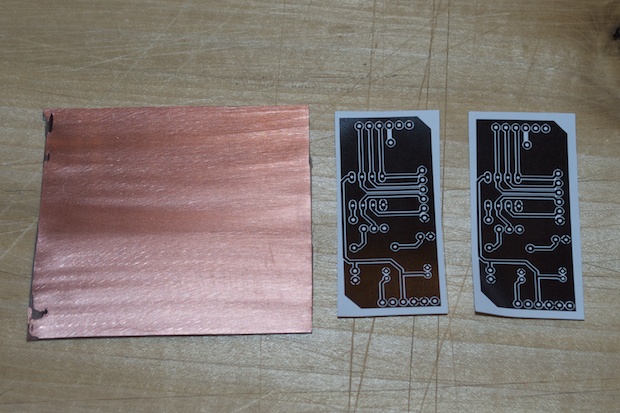

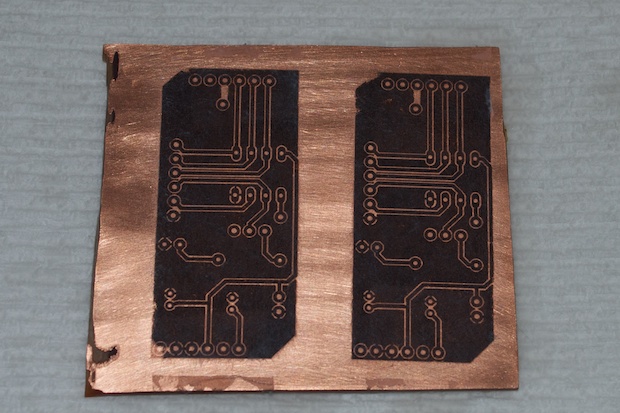

I started by cleaning a small copper board that I cut from an old 12”x12” panel. I then printed out two PCBs onto white paper.

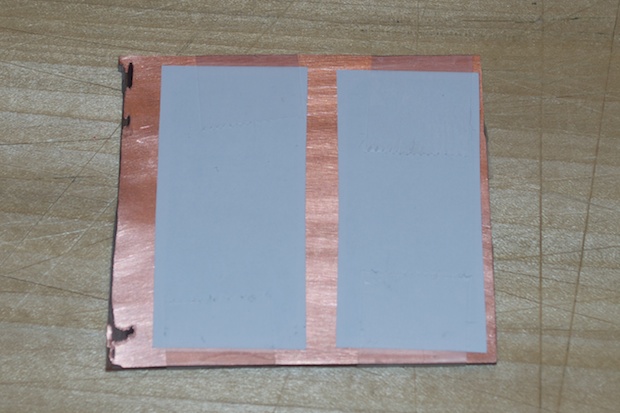

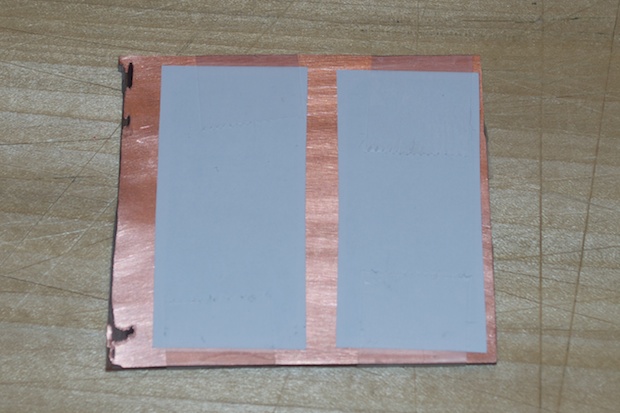

I taped the printouts to the board.

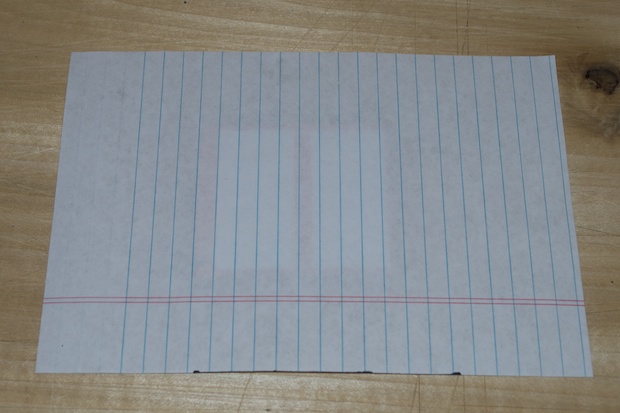

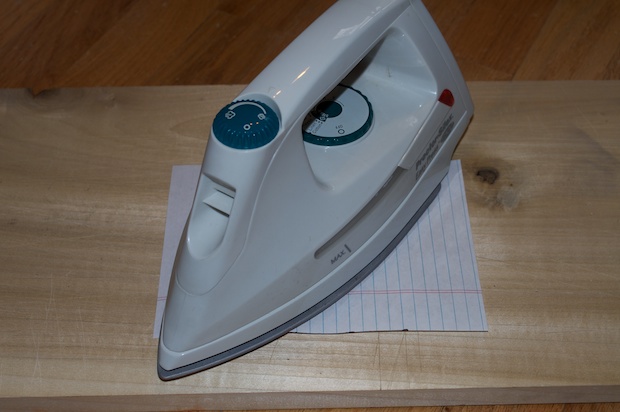

I covered it with a piece of papers so that the tape wouldn’t melt to my iron.

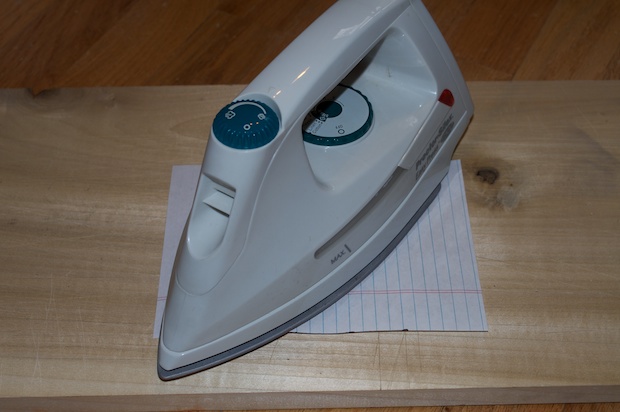

I then ironed it for a few minutes so that the toner would remelt to the copper board.

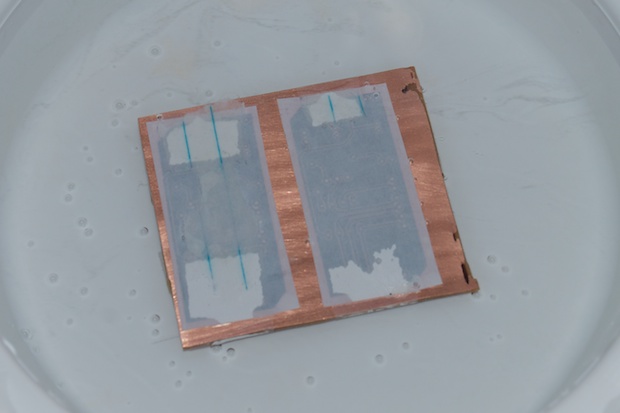

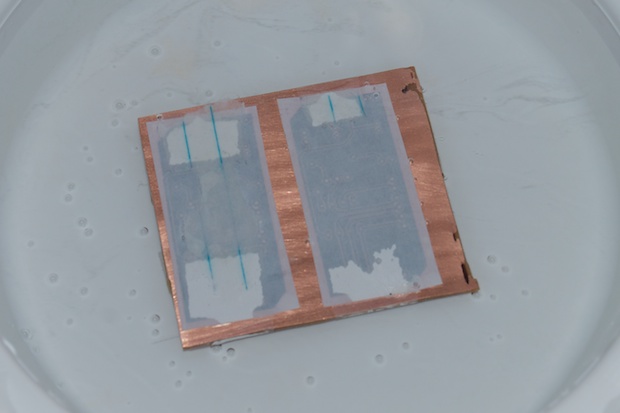

After a few minutes under the iron, I soaked the boards in hot water to remove the paper.

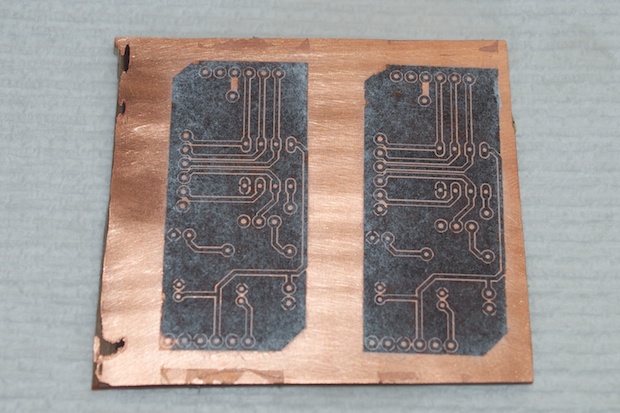

Pretty stubborn stuff. The problem with my laser printer is that the toner is wax based. This gives your text and images a nice glossy sheen, but I think it’s bonding with the paper too well. It’s really hard, if not impossible, to separate the paper from the toner.

After 5 minutes in scalding hot water, the paper had barely started to come away. I rubbed some off with my fingers, but I didn’t wan’t to rub too hard fearing that I’d take the toner with it. I put it back in the hot water for another 5 minutes.

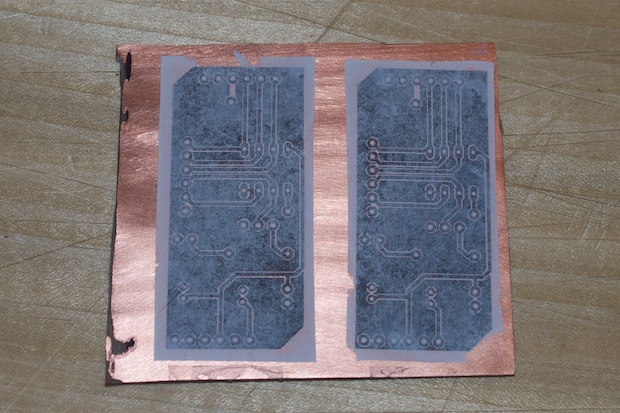

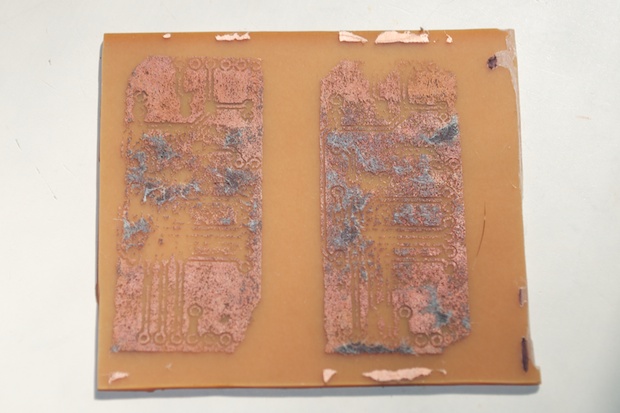

After a little more rubbing it looked like I’d gotten it all off…

But as soon as it dried, it was apparent that there was still a layer of paper on top of the toner.

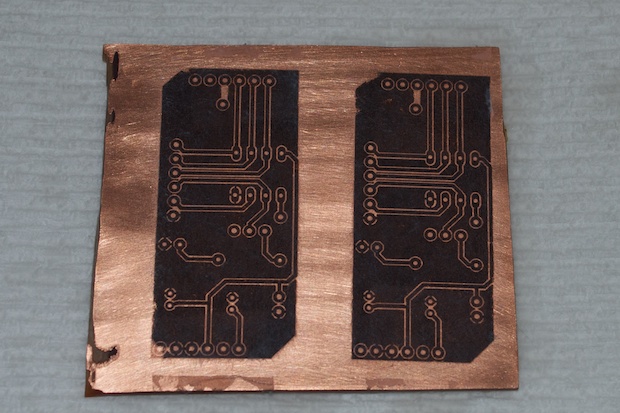

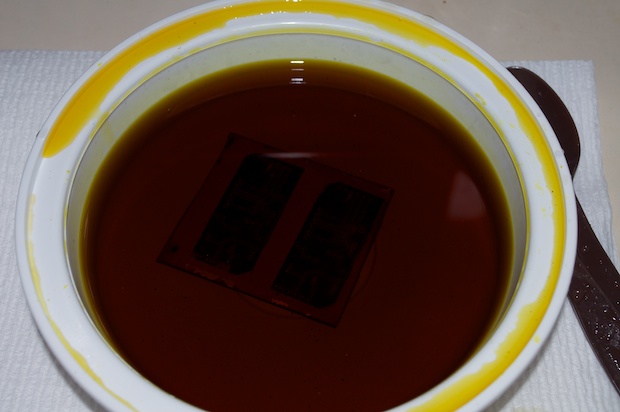

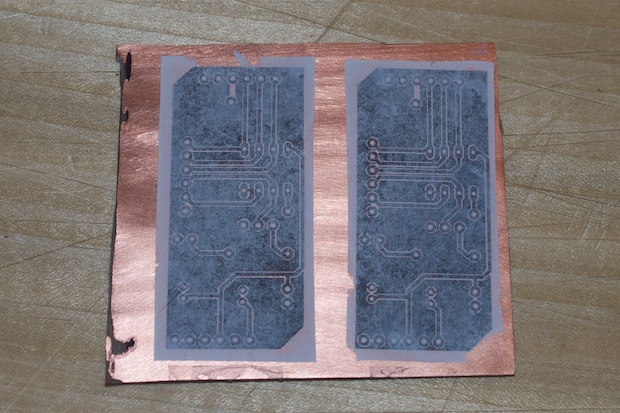

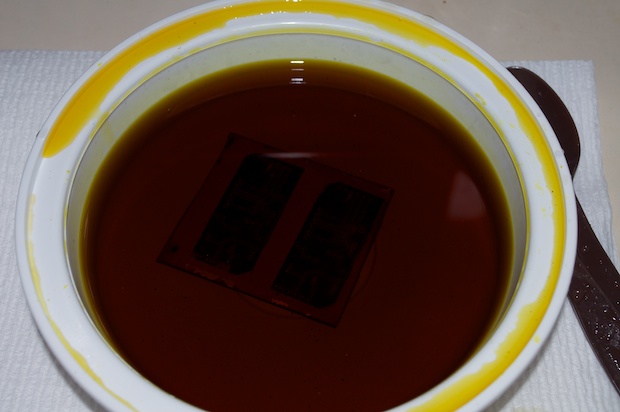

I kept at it until I got off whatever I could. I then dropped it into the etchant for 15 minutes.

After about 15 minutes, it hadn’t done much. I added some more etchant to the mix and let it sit for another 20 minutes.

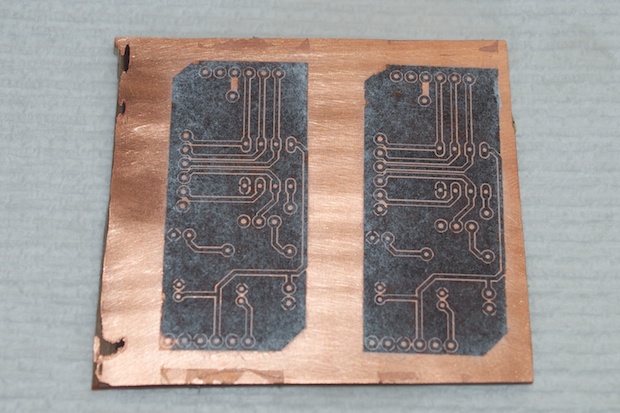

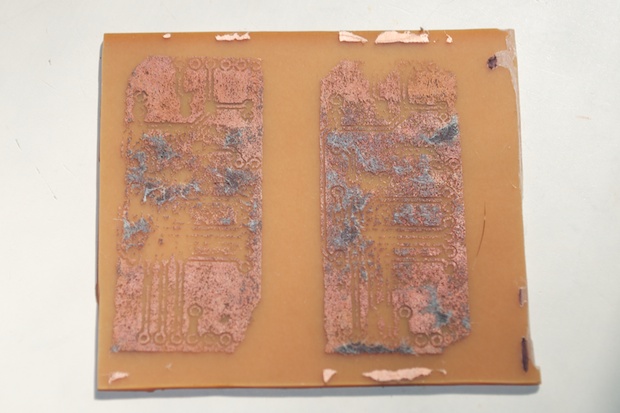

It looked like the toner was still on the board, but when I rubber it off it was clear that just like before, the etchant had eaten right through the toner.

The fact that the mix was stronger and I left it in longer made things worse.

I guess that answers that question: the toner transfer method is a no-go.

Maybe I’ll try a pretreated board and a UV light?

See this project from start to finish: Playing with the ATtiny85 Etching at Home - A Dry Run Etching at Home: Take 2 (FAIL!)

ATtiny Programming Shield