I have so many ideas for things to print, but I don't want them all in blue! I need new rolls of filament! My wife ordered 3 rolls of filament for me on the same day that she ordered the ROBO 3D, but Amazon broke up the order and shipped them out on different days. Not to mention, President's Day delayed it an additional day.

After waiting a few extra days, my patience was rewarded with the delivery of 3 rolls of filament. Actually, I goofed and added a gray roll of HIPS to my Amazon wishlist. Needless to say, my wife ordered it without question. It was supposed to be PLA.

Since my ROBO 3D is all up and running and I have pounds and pounds of filament, it was time to start churning out some prints.

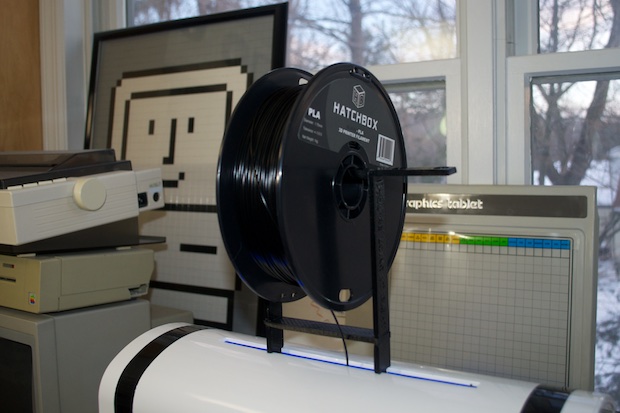

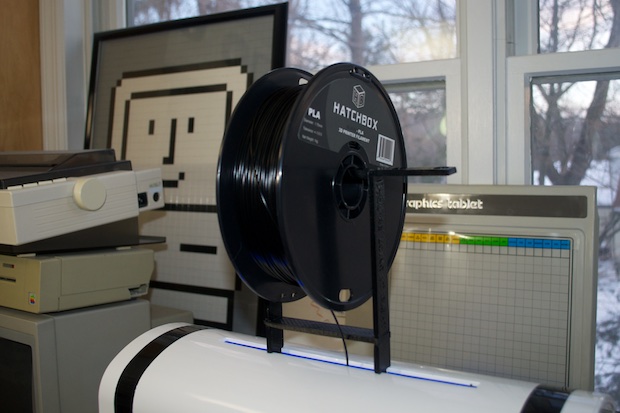

I first started out with a new and improved filament holder. I didn't like the way that the stock holder is on the back. The filament has to go up and over from the side. From what I've read, everyone seems to agree that it's better to have less tension on the filament and have it come straight down from the top and into the extruder.

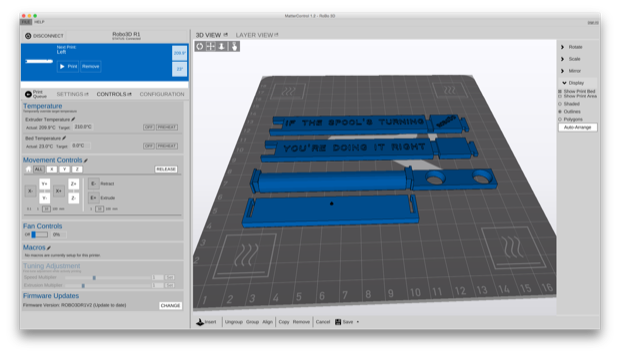

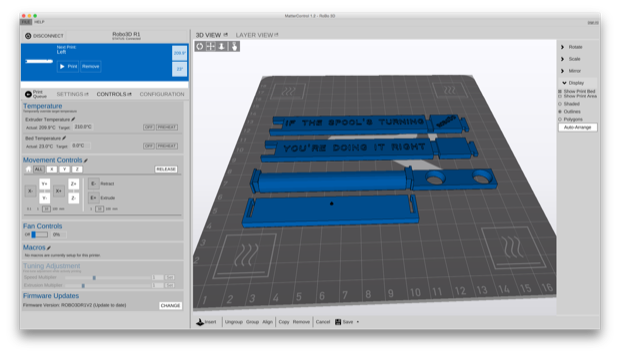

I hopped on Thinigverse and downloaded the

ROBO 3D Spool Holder.

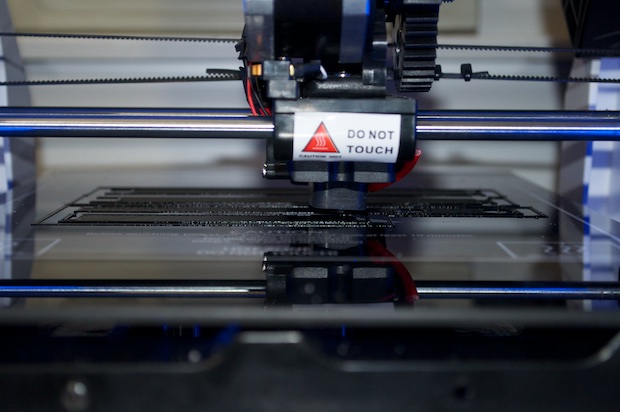

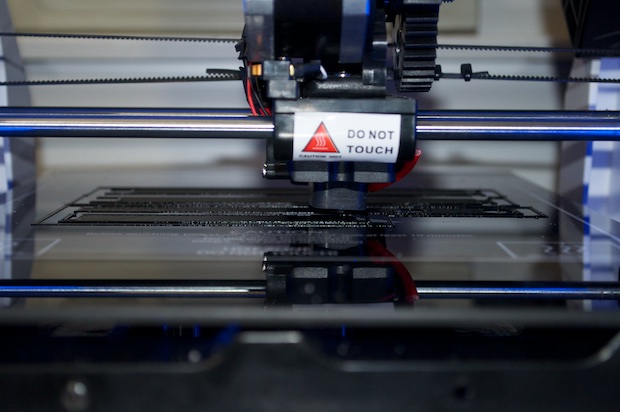

I printed it in black. The first few layers went down pretty well.

About an hour later, I could see that the corners of the smallest piece were starting to lift. I paused the printer and tried to get a little more stick under the ends. I then raised the bed temperature from 50 degrees to 65. I then pushed the part down with my scraper in an attempt to get it to stick back down.

It worked pretty well. There was still a little curling at the end, but not enough to mess up the part. The whole thing was very tight going together. I took a little file and cleaned up the slots and tabs and it went together perfectly.

PLA is a lot stronger than I thought. It's practically indestructible. Even some of the smaller test pieces that I've printed are surprisingly strong, and are unbreakable by hand. I bet I could run them over with my car and they'd hold up.

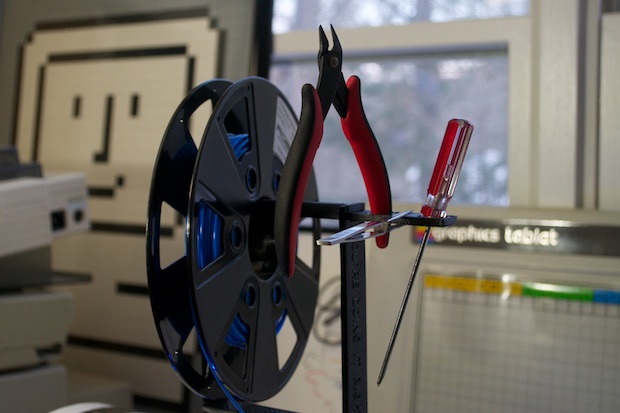

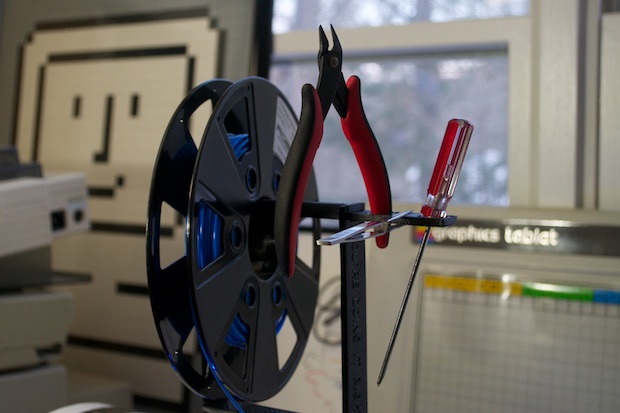

I also like how this version has a little tool holder on the side. A nice touch.

It's funny, because I waited almost a week to get the black, gray, and white filament, and the first thing I needed to print for a repair turned out to be blue!

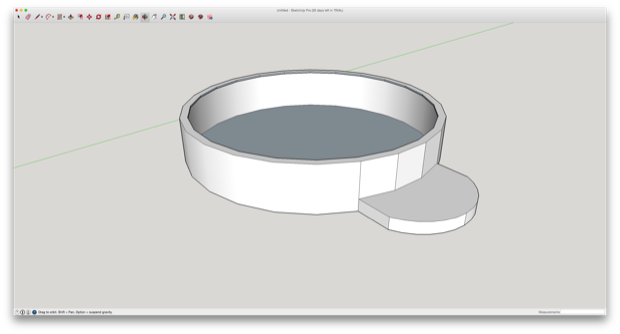

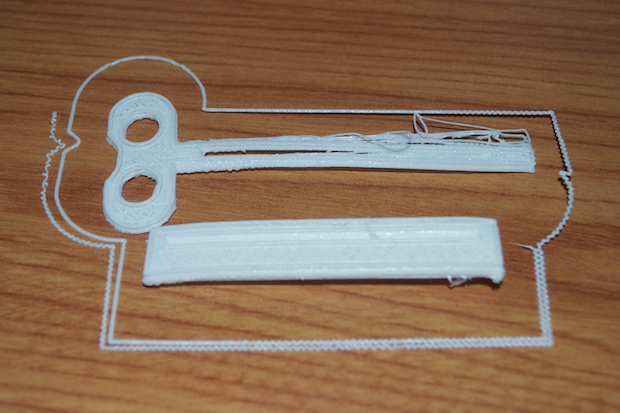

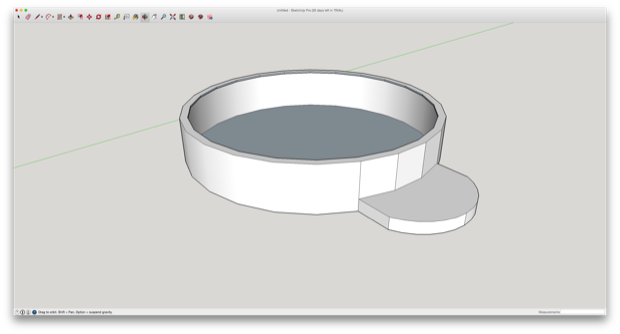

I filled my wife's windshield washer reservoir the other day and when I closed the cap, my thumb went right through the cap. I guess the plastic has gone brittle over time. We both have matching minivans, so I popped my hood and removed my cap. I brought it inside and measured it with my caliper. I wanted to just bang this out, so I chalked up a simple 3D model in SketchUp. I haven't really tried my hand at modeling anything for 3D printing yet, so the only software I have is SketchUp. I haven't really explored all the details and requirements on how to do it, but I found a SketchUp plugin that allows you to export a model to a .stl file. I figured I'd give it a go.

I didn't go nuts with the details, and I wasn't looking to make a one-to-one copy; just something that looks like a windshield washer cap.

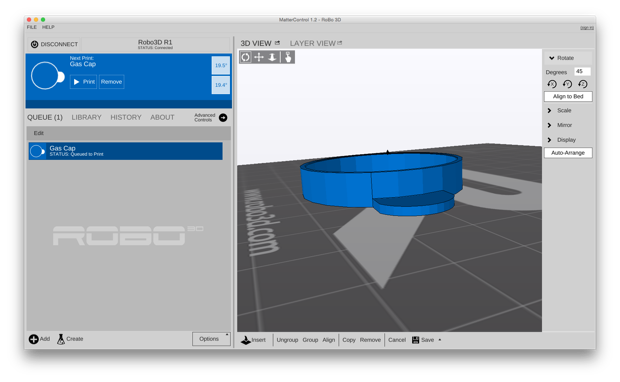

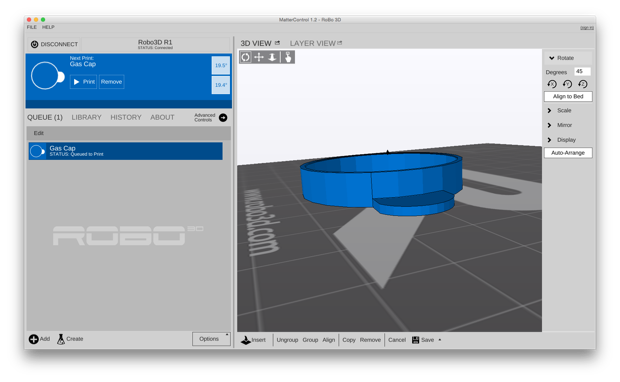

For some reason, the little tab that I put on the side shows up in the ROBO 3D app, but it doesn't print. Like I said, I haven't worked out the subtle nuances of designing a model for 3D printing. I've also read that SketchUp isn't particularly good at generating printable files.

Since it's blue, I figured I'd print it in blue.

It fits like a glove.

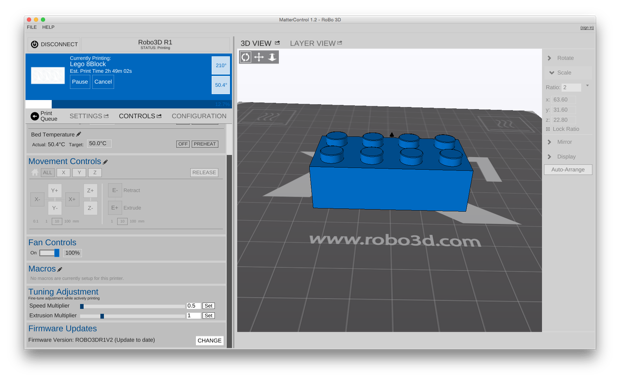

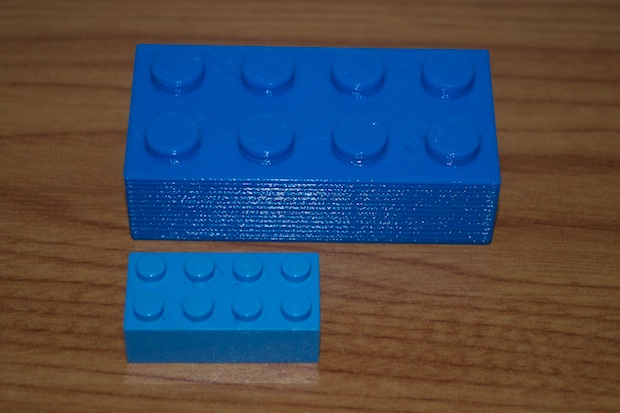

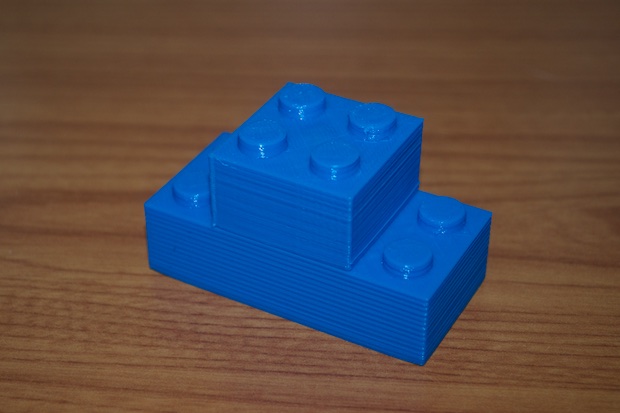

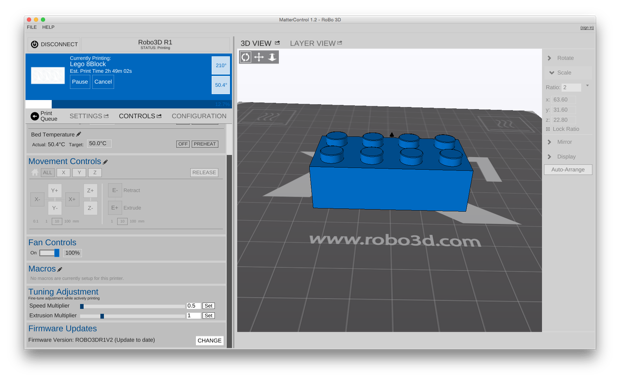

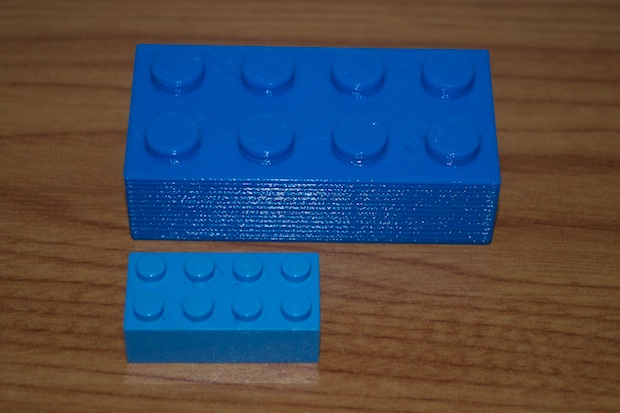

I wanted to print a giant LEGO brick. I was going to print it in black, but I figured blue would stand out more on my desk. Go figure, more blue. I could have printed one last Saturday.

I found an

8x2 LEGO brick on Thingiverse and scaled it up 2X.

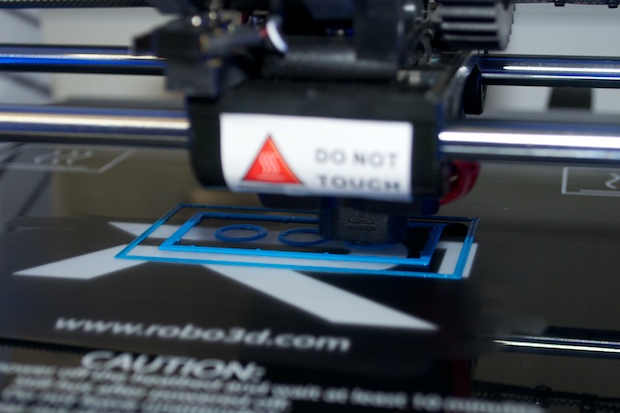

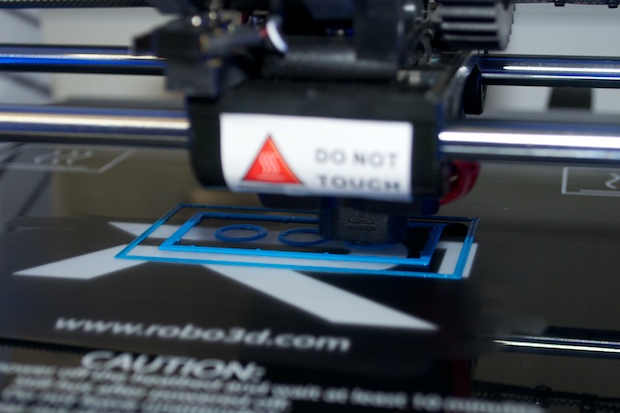

It started to print. I asked my kids what they thought it was going to be and they said, "Boom! Giant LEGO brick!" Awesome.

It took almost 3 hours to print at .2mm, but it came out sweet!

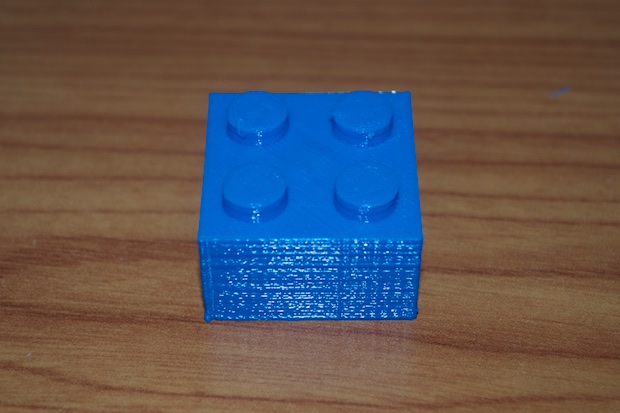

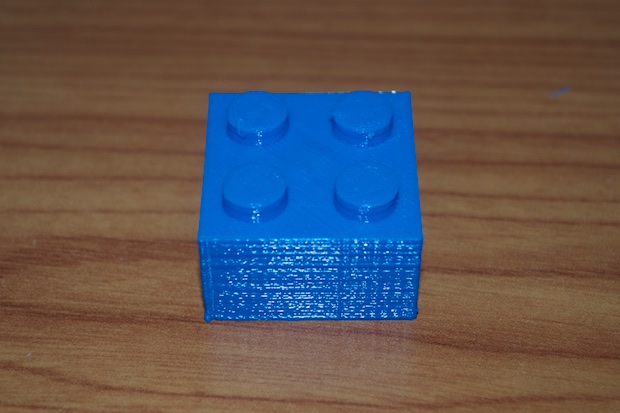

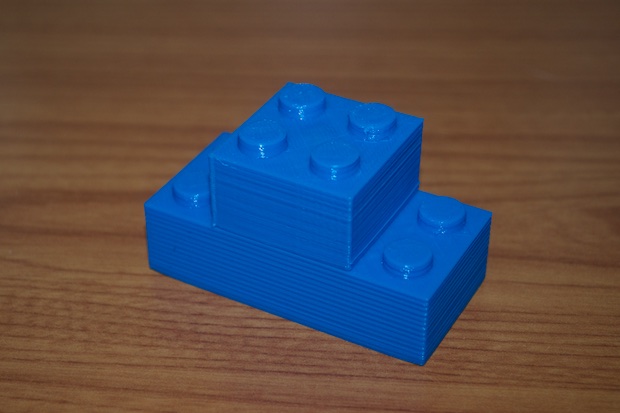

I then decided to try another one. This time, a 2x2 brick.

They are perfect. They snap together like real LEGO bricks!

Now for something in black!

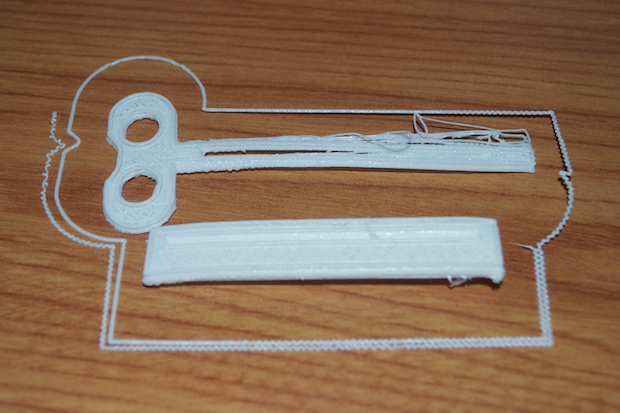

The names plates for the kids came out a little wonky on the top, but not a bad trial run. They probably just need a little cleaning up with an X-Acto knife.

I joked around with a friend at work saying that this plastic was so strong, you could probably make a pair of brass knuckles. Jokingly, I printed one. It came out too small, so I scaled it up. Silly me went too large and left the print unattended. When I came back, I was surprised to see how large I made it. If this fits your hand, you don't really need brass knuckles.

I tried a few prints with the gray HIPS, but things kept curling up at the edges. I need a better way to get them to stick to the bed. Maybe blue painters tape? Everyone raves about it.

Now for some ABS. This stuff is a little trickier. The bed temp has to be higher than PLA, as well as the extrusion temperature. I kept trying to set the bed temperature to 90 degrees since it's recommended that the bed be somewhere between 80 and 110. I couldn't for the life of me get both temperatures to reach their targets at the same time. The extruder would reach 230, but the bed wouldn't reach 90. Once it hit 85, the extruder would cool off. I spent all day messing around with it until someone in the ROBO 3D forums explained that there is max bed temp of 85 degrees set in the firmware. Once tripped, the machine will shut down. That explained it. With this new information, I tweaked my settings and tried another print.

This was supposed to be a toothpaste squeezy thing. I got the machine to finally print, but it just came right off the bed.

I tried it again and slowed things down a bit hoping that less jarring back and forth on the piece would stop it from coming up off the bed. Unfortunately, I turned my back on it for 5 minutes and disaster struck. Total fail.

As far as ABS goes, I'm going to quit while I'm ahead. I'll have to pick up a can of hairspray and see if that helps. In any case, 3D printing is awesome! Now to hop online and order a bunch more colors!